The twenty-first century

The twenty-first century

will be wind, solar, and hydro

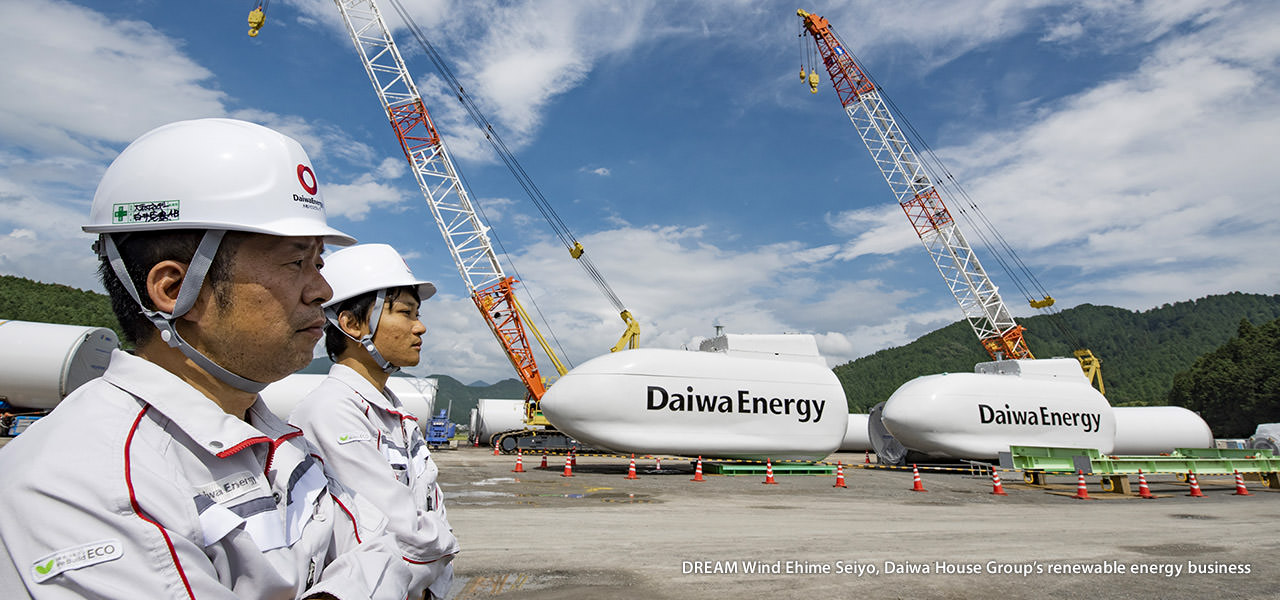

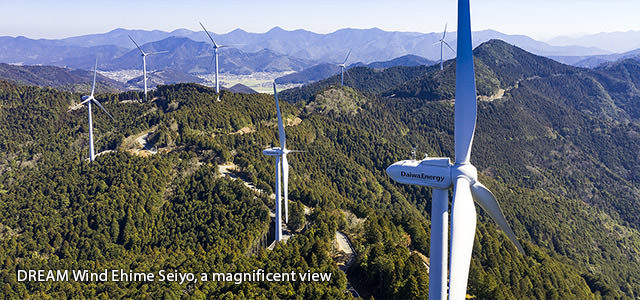

Daiwa House Industry’s founder once predicted that “The twenty-first century will be wind, solar, and hydro.” Its DREAM Wind Ehime Seiyo project to make that idea a reality in the form of wind energy was completed in 2020.

![]()

![]()

![]()

![]()

![]()

Moving toward the Daiwa House Group’s second wind power plant

There is a long, thin peninsula in Ehime Prefecture, Japan called Sadamisaki Peninsula that extends from the westernmost part of Shikoku. On that peninsula is a forest of huge wind turbines that are turned by the strong winds that blow from the sea. Nine of these turbines make up DREAM Wind Sadamisaki, Daiwa House Group’s first wind power plant. Daiwa Energy is in charge of management and operation.

The plant started operating in 2007. Nine wind turbines generate a maximum output of 1,000 kW (1 MW) per turbine and produce 30,484 MWh *1 of power per year. The amount of power used per year, per household is equivalent to enough power for approximately 6,800 households *2.

Daiwa House Group has been in the construction business since its founding. Why did the company build its own wind power plant and start creating energy? The starting point was in the 1990s, when the founder predicted that “The twenty-first century will be wind, solar, and hydro.” Time passed, and the founder’s ideas have been made into reality as wind power generators and solar power generation systems. Finally, DREAM Wind Sadamisaki has come to fruition as a major turning point for Daiwa House Group’s environmental energy business.

Mr. Shimakawa is currently an Executive Officer at Daiwa Energy and the head of the Management Strategy Office and Electric Power Division. In 2007, he was involved with managing DREAM Wind Sadamisaki as the Engineering Manager.

The next chance to continue beyond Sadamisaki came in 2012. Shikoku Electric Power decided to recruit new power companies in order to increase the amount of wind power generated. This was the opportunity Daiwa Energy had been waiting for, where it could use its accumulated strengths. Daiwa Energy applied to be one of the power companies, went through evaluations and the selection process, and started the DREAM Wind Ehime Seiyo project as Daiwa House Group’s second step. The proposed site was in the city of Seiyo in Ehime Prefecture.

Mr. Shimakawa prepared environmental assessments and considered who he would send from the company to the site as a manager. There was a suitable person. It was Mr. Shirai, who would travel between different companies and departments in Daiwa House Group and boldly face a new world.

- *1: Actual results in FY2018

- *2: Based on a total power consumption per household of 4,432 kWh per year. Calculated based on the 2019 Energy Conservation Performance Catalog issued by the Agency for National Resources and Energy in the Ministry of Economy, Trade, and Industry.

Going to places where there were no roads

Mr. Shimakawa told Mr. Shirai, “Go to Seiyo.” Mr. Shirai was in the Energy Conservation Division and this was his first foray into renewable energy. He had never even seen an actual wind power generator before. At first he thought, “Am I the right one to do this?” But he was the type of person who enjoys making a difference by doing new things, and he was excited by the idea of a new challenge.

In 2012, Mr. Shirai headed to Ehime. In order to decide where to build the wind turbines, he needed to investigate the wind conditions for more than a year. Team members from the Osaka Urban Development Department at Daiwa House Industry also assisted Mr. Shirai in this endeavor.

They were going to build eight wind turbines. All of the proposed sites were on the tops of mountains. The altitude was 400-450 meters. Mr. Shirai and his team traveled through places where there were no roads, cutting grass, hacking through brush, and climbing mountains. There were also steep slopes they had to crawl up on their hands and knees. They wanted to leave the natural environment in its current state as much as possible. They looked for a place that was close to existing roads where they could minimize the construction preparation area, access roads, and trees that needed to be cut down, and leased the land. They installed a tower (60 meters tall) there for observing the wind conditions, and observed the wind conditions for a year. The team became confident that the project would be successful at that site, so they negotiated and consulted with all the landowners and local people, and concluded agreements for leasing the site. In 2018, the time for construction had finally come.

Experts in all the relevant fields worked with Daiwa Energy, the business owner, as part of the DREAM Wind Ehime Seiyo project team. Daiwa House Industry also continued to participate, and was in charge of the basic design of the wind turbines. Shimizu Corporation did the civil design, Nippon Express handled transportation, and Yonden Engineering took care of the electrical work.

Transporting parts from ports to the tops of mountains

Watching the assembly process

Transporting huge blades to the top of the mountain

The wind turbines consisted of four major parts. First, the land was prepared for construction, a concrete foundation was laid, and a tower was built as the pillar. On the top, a nacelle was installed that stored the generator. On the back, the blades and a junction area called a hub were attached. The total height including the blades was 121 meters, which is about the same height as a 34-story building. Each part was enormous. The blades were 42 meters long, and the tower was 78 meters tall.

The wind turbines were made by Japanese companies, but the blades and towers were manufactured elsewhere in Asia, where the world’s wind turbines are produced. The blades were transported from China, and the tower was separated into four parts and transported from S. Korea on an 8,000-ton-class ship. The cargo went through customs procedures in the Port of Sukumo in Kochi Prefecture. Then, each wind turbine was re-loaded onto a 3,000-ton-class barge, and then unloaded at the Port of Mikame, in the city of Seiyo, Ehime Prefecture.

The turbines were transported in vehicles from the Port of Mikame to the site.

Wind turbine parts that arrived from China and South Korea

Transporting these turbines over land was a high hurdle to overcome in the wind turbine construction project. The route along the prefectural road passed through residential areas, and then was a winding mountain road. Loading 42-meter blades and going up narrow mountain roads with them was an extremely difficult undertaking. A re-loading site was prepared at the halfway point. The first leg of the journey from the port to the re-loading site consisted of a large trailer traveling overnight into the morning. The second leg of the journey to the site consisted of closing the prefectural road to traffic in all directions from the morning to mid-afternoon and transporting the parts in a special transport vehicle at 4 kph, the same speed as a person walking.

Nippon Express’s transport vehicle had the feature of being able to move the loaded blades both vertically and horizontally, and could turn the blades or make slight adjustments to the angle. Therefore, it was possible to minimize the trees that needed to be cut down along the road and minimize the width of the roads. This transport vehicle was an optimal part of the project team from the viewpoint of environmental considerations.

Turbine 8, which had the best wind conditions, was the most difficult to transport. There was an elevation difference of 50 meters from the road to the construction site. The access roads were switchbacks that zigzagged in sharp curves. It was extremely difficult to drive the transport vehicle, but the team cooperated and was able to transport the parts safely.

Unloading parts at the Port of Mikame in the city of Seiyo

Construction site for Turbine 7

Going up a narrow switchback road

Swaying in the wind 78 meters above the ground

The culmination of assembling the wind turbines was probably attaching the blades. Four or five team members climbed a ladder inside the 78-meter tower, waited in the junction area at the top, and attached each blade that was suspended from a crane. When the wind blew, the blades turned and swayed in the wind.

The wind was the greatest enemy of the wind turbine construction work. When a strong wind blew, construction stopped. For that reason, assembly normally took place in the summer, when the wind was light, and test runs were done in the winter, when the wind was strong. However, 2018 was the exception. In July 2018, western Japan was assailed by torrential rains and record heavy rainfall. The construction site was not damaged, but nearby cities, towns, and villages suffered major damage. The workers worked hard to aid the local people in recovery efforts, and construction continued quietly, with half the personnel. In the following year, 2019, there were many disasters, such as heavy rainfall, typhoons, and earthquakes, but the company kept revising the schedule and aimed to complete construction.

After assembly was finished, the electrical work was done, and elevators were installed in the towers. Also, most of the power transmission facilities between the respective wind turbines and between the wind turbines and transformer substations were buried underground. This made it possible to minimize the trees that needed to be cut down in the power transmission path and kept artificial structures like steel towers and utility poles from detracting from the natural beauty. This also became a power transmission facility that is strong against storms and other disasters.

The first wind turbine was completed in July 2019. Mr. Shirai thought, “Ah, we have finally built the first one,” but he had no time to catch his breath. Daiwa Energy’s young employees and Mr. Yamamoto worked to supervise the construction as the business owners. Mr. Tamaru, who was in charge of the maintenance after completion, understood the construction history, and watched over the construction on the site. Mr. Shirai spent weekdays in Ehime, and went home to Osaka on an overnight bus on weekends. His boss, Mr. Shimakawa, had entrusted him with the project, saying “You’re in charge of the next wind power plant,” but seven years passed before he knew it. His child, who had been little when the project started, was already in the higher grades of elementary school by the time the project was completed.

The large team devoted their enthusiasm and a long period of time to DREAM Wind Ehime Seiyo, which started operating on March 16, 2020.

People and life lie beyond the wind turbines

DREAM Wind Ehime Seiyo has eight wind turbines that generate a maximum output of 2,000 kW (2 MW) per turbine for a total of 16,000 kW (16 MW) of power. The planned amount of power to be generated per year is approximately 35,000 MWh, which is enough power for 7,800 general households.

This major project could not have been completed without the cooperation of the locals and people from inside and outside the company, and Mr. Shirai was thankful for their help. He thought, “I was always an intermediary, and I wanted to be the conductor that directed the orchestra.” He had the role of overseeing everything, and talked to the local people so that he could be an intermediary between them and the construction staff. Everyone worked hard in good faith, and sometimes people admitted, ”If Mr. Shirai says so, that’s what we have to do.”

“My favorite thing is talking to people. It’s interesting,” Mr. Shirai said. Mr. Shirai knows that no matter how huge of a wind turbine you build, people and life lie beyond that, because the renewable energy business has a symbiotic relationship with the people of the region and will continue to contribute to life in Japan and the world for a long time.

Daiwa House Group has the goal of building and operating renewable energy power generation facilities that generate more power than the Group uses, by 2030. To that end, the Group is developing power generation facilities that generate renewable energy such as wind, solar, and hydro power. At the end of FY2019, the Group managed 253 renewable energy power generation facilities throughout Japan. With the completion of DREAM Wind Ehime Seiyo, Daiwa House Group has built one more.

“The twenty-first century will be wind, solar, and hydro.” The future that the founder described is becoming a reality, one step at a time.

Building trust relationships with people inside and outside the company

Wind turbines, the new scenery in Ehime

*The information in the article was current as of March 2020.

-

"A Free Hand to Design a New World of Luxury Houses"

"A Free Hand to Design a New World of Luxury Houses"

-

"The next mission in construction business"

"The next mission in construction business"

-

"An Athlete’s Flying Start to His Second Life"

"An Athlete’s Flying Start to His Second Life"

-

"Tackling the Challenges of Carbon Neutrality"

"Tackling the Challenges of Carbon Neutrality"

-

"Building Close Relationships with Our Customers"

"Building Close Relationships with Our Customers"

-

"Transforming the Construction Sector with DX"

"Transforming the Construction Sector with DX"

-

"Bringing Ever-More Joy to Travel in Japan"

"Bringing Ever-More Joy to Travel in Japan"

-

"Regeneration" Arises from New Construction

"Regeneration" Arises from New Construction

-

"An Enduring Spirit of Hospitality"

"An Enduring Spirit of Hospitality"

-

"Collaborating with 16 creators invited from around the world"

"Collaborating with 16 creators invited from around the world"

-

"Passing Down Hometown to Future Generations with Renewable Energy"

"Passing Down Hometown to Future Generations with Renewable Energy"

-

"The twenty-first century will be wind, solar, and hydro"

"The twenty-first century will be wind, solar, and hydro"

-

"Be a Pioneer in the Design Revolution"

"Be a Pioneer in the Design Revolution"

-

"Building better places to live through partnership between the public and private sectors"

"Building better places to live through partnership between the public and private sectors"

-

"Supporting the foundations of the nation"

"Supporting the foundations of the nation"

-

"Continuing to work the rest of life"

"Continuing to work the rest of life"

-

"Doing our best to support post-disaster reconstruction"

"Doing our best to support post-disaster reconstruction"

-

"Defying common wisdom in housing construction"

"Defying common wisdom in housing construction"

-

"Develop the American market!"

"Develop the American market!"

-

"Exporting Japanese industrial parks"

"Exporting Japanese industrial parks"

-

"Industrializing agriculture"

"Industrializing agriculture"