Be a Pioneer

Be a Pioneer

in the Design Revolution

Following world trends, significant changes are underway in Japan’s construction industry. As one of the pioneers, Daiwa House Industry is in the process of introducing “D’s BIM,” a revolutionary workflow.

![]()

![]()

![]()

The start of D’s BIM, an innovation in construction

The day of self-driving cars is not a dream, shops now accept electronic money, and when people go home, appliances operate using the IoT. In 2020, when times are changing significantly, historic earthshaking changes are also emerging in Japan’s construction industry.

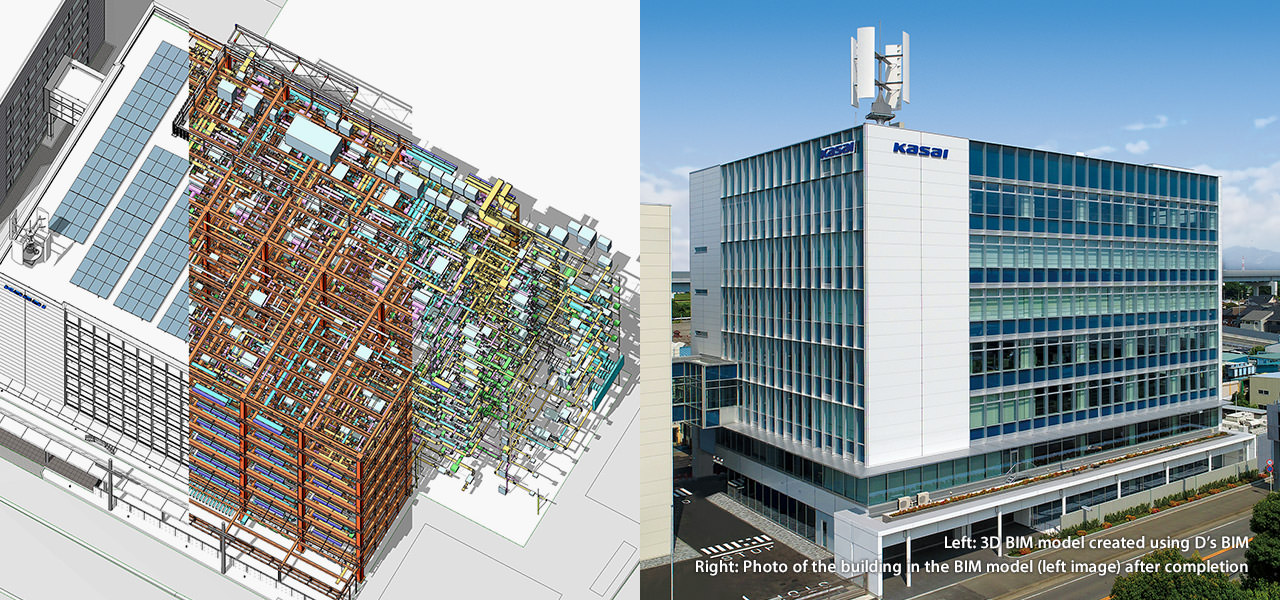

BIM (Building Information Modeling), a revolutionary workflow, is playing the main role. Normally, buildings are designed by creating drawings in 2D CAD or by drawing 3-dimensional shapes in 3D CAD. With BIM, 3D parts are assembled, and a digital model is created, but the major differences come before that. Attribute data such as specifications and performance for components and materials, part numbers of equipment, and prices can be added for each part that makes up the model. And if a correction is made to an area, it is automatically reflected in all of the data. There is no need to manually make revisions like people have been doing up until now, which makes it possible to eliminate problems and waste. Then, comprehensively linking this information from the plan design to the implementation design, construction, and maintenance management makes it possible to increase work efficiency and dramatically increase project quality.

More specifically, BIM isn’t just a single technology--it is an innovation that changes the construction workflow itself from its foundation.

Globally, BIM spread first to Europe and North America, and 2009 was the year when there was an upsurge in BIM in Japan, so it is called the “First year of BIM.” Daiwa House Industry quickly noticed the potential of BIM, and started using Revit (made by Autodesk) to do research in 2006. Revit is the BIM software with the most users in the world. Then, the company launched the BIM Promotion Office in 2017, while proceeding with verification and management. The following year, in 2018, the BIM Promotion Office became the BIM Promotion Department, and a business partner agreement was concluded with Autodesk. The company aimed to use D’s BIM, which was based on Revit, to completely change to BIM companywide, and those activities are fully underway.

The 4 pillars: Creating culture, cultivating people, manufacturing goods, and creating emotional connections

Mr. Yoshinaka is the head of the BIM Promotion Department, and gave this declaration in front of the department members, regarding the goal of changing to BIM. “In FY2020, let’s aim to make a 100% change to BIM for design using our major product xevoΣ (xevo sigma) for low-rise apartments, construction-type buildings, and houses!” The company is also looking to implement this for high-rise apartments and wooden houses.

On the topic of the apartments where BIM was introduced early, the company successfully changed 80% or more of all properties to BIM. However, that journey was fraught with extreme difficulties, something like hacking one’s way through a primitive wilderness. And the percentage of subsequent construction-type buildings that changed to BIM was approximately 30%. Houses are starting from zero. Since the time of its founding, Daiwa House Industry has pursued the industrialization of construction, and despite the company’s high affinity for BIM, considerable effort and speed have been required.

Apartment where D’s BIM was introduced early

Something that has stood in the way has been designers’ so-called “allergy to BIM.” One of the advantages of BIM is called “front loading.” This is a method that involves spending time on design in the initial stages so that problems don’t occur in the future that cause processes to be redone or reworked and increase costs. This places a heavy burden on designers, and this is where the allergic reactions emerge. Even if designers are told to change to Revit from the CAD they are familiar with using, it’s a race against time to complete the work at hand. For example, even if designers start using it themselves, introducing BIM to areas such as construction and maintenance management is a future discussion. For that reason, people can’t see results quickly, which doesn’t provide much motivation. Resistance to BIM is a wall that many companies who looked into introducing it have run up against.

Mr. Yoshinaka was also keenly feeling the difficulty of introducing BIM to apartment design sites. However, the real function of BIM is linking information, which is the next step after changing 100% of design to BIM. Various approaches are needed to make all employees aware of that advantage.

Mr. Yoshinaka came up with 4 basic policies for activities to promote BIM: Creating culture, cultivating people, manufacturing goods, and creating emotional connections.

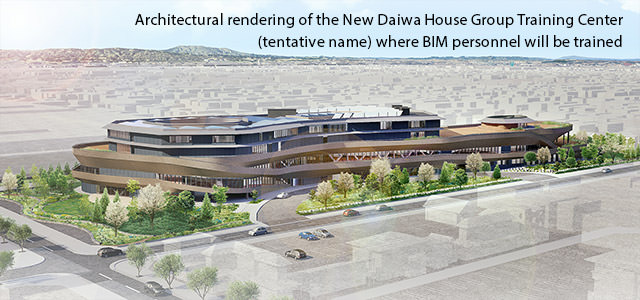

“Culture” refers to corporate culture. This means how Daiwa House Industry is creating a new culture mainly by using D’s BIM to challenge the methods that had been used for decades, and changed employees’ lifestyles and how they work. “People” refers to human resources. Developing human resources who understand D’s BIM and utilize it in actual work influences the company’s future. For that reason, the company created BIM Training Centers in Tokyo and Osaka, and all 2,000 designers are taking classes. Some training has started for people who work in the area of construction, and people in charge of sales are also scheduled to take classes in the future. As for “goods,” with Revit as a common language, information = manufacturing goods. Because, if the words can be understood, then different departments, group companies, and business partners can communicate.

Mr. Yoshinaka’s personal opinion is that he wants to contribute to raising the standards of the construction industry and create an emotional connection with society by managing D’s BIM as an innovation that is also open to outside organizations in industry, government, and academia.

In 2019, the time came to move toward implementing that idea.

Astounding presentation by 2 new employees

In October 2019, Typhoon 19 caused serious damage in places such as Kanto, Koshin, and Tohoku. Requests for temporary emergency housing rushed in from affected areas in the city of Nagano. D’s BIM is a way to build things even one day faster than usual. As part of generative design that automatically generates countless design proposals, during joint research, Kumamoto University, Daiwa House Industry, and Daiwa Lease decided to use a program that automatically generates layout plan proposals.

Four members of the BIM Promotion Department participated. The team entered the site at 10 AM, and started consulting with a government official. They investigated the site in the afternoon, and then investigated multiple building layout proposals that the automatic generation program had created. On the second day, they investigated the site again, completed the drawings and simulation videos, and attended the presentation for the government at 5 PM.

In the videos that showed realistic representations of the completed site, the shadows of the buildings moved as time passed. The trees on the site were also reproduced. The government official had also been in charge of the temporary emergency housing for the Kumamoto earthquake in 2016. At first he said, “I can understand it with just a plan view, so there is no need for BIM.” But after he finished looking at it, he changed his impression, and said “BIM is amazing, isn’t it?”

Perspective drawing and layout drawing of temporary emergency housing using D’s BIM

Sunlight simulations are also proposed as videos

Temporary facilities at Showa no Mori Park, which were completed in a short time

In the past, it would have taken 7 days from the time the consultations started to when the layout was approved. But with BIM, it only took 2 days. From the start of design to completion, it would have taken 2 months, but the company was able to shorten it to 35 days, which is approximately half that.

“D’s BIM” has achieved astounding results. And 2 new employees tuned it there on site and created the videos. They studied BIM in a college seminar, and showed everyone wonderful work, after only having worked for the company for 6 months. Mr. Yoshinaka laughed, “I want to stand tall and brag about them.”

Then the 4 basic policies were made into reality: Corporate culture embodied the founding spirit of “Speed is the biggest service,” young human resources worked hard as BIM leaders, cutting-edge manufacturing was achieved using Revit and the automatic generation program, and a real emotional connection was formed between victims and the government. It is true that the road to completely changing over to BIM is difficult, but there is no end to the benefits to be gained.

Digital transformation is changing the way people live and work

In 2017, the BIM Department started with only 5 people, but it now has a large staff of more than 60 people. It is the most rapidly growing organization in the company, which demonstrates that Daiwa House Industry is putting considerable effort into BIM. That concentration of effort can also be seen in the investment plan. In the Daiwa House Group’s 6th Medium-Term Management Plan, it was announced that out of the 250 billion yen for capital investment, 100 billion yen could be allocated to things such as digitalization for BIM.

Digital construction has also started, which is the next theme for building BIM. Daiwa House Industry wants to use digital construction to reduce personnel and use full automation on sites by utilizing things like BIM to achieve construction using digital data as-is, with the aim of using robots and AI to reduce the workers on housing construction sites to about 80% after 2 or 3 years. Remotely and digitally managing tests on sites from remote management centers in Tokyo and Osaka will be a step forward.

Furthermore, the global construction industry is working toward using Design for Manufacture and Assembly (DFMA) and digital technology to achieve design that reduces the man-hours needed for manufacturing and assembly. Because Daiwa House Industry is a trailblazer in industrialized construction and excels in this field, this trend is a big opportunity for the company.

Further in the future, Daiwa House Industry is looking to lead in society as a cutting-edge company that uses digital transformation (DX) to fully utilize digital construction and DFMA.

D’s BIM, the platform that can digitally link different departments, different fields, and different countries, will probably lead to dramatic changes in business models and the way people live and work. It can also contribute to achieving global SDGs (sustainable development goals). D’s BIM is the start of everything and a key technology.

*The information in this article was current as of February 2020.

-

"A Free Hand to Design a New World of Luxury Houses"

"A Free Hand to Design a New World of Luxury Houses"

-

"The next mission in construction business"

"The next mission in construction business"

-

"An Athlete’s Flying Start to His Second Life"

"An Athlete’s Flying Start to His Second Life"

-

"Tackling the Challenges of Carbon Neutrality"

"Tackling the Challenges of Carbon Neutrality"

-

"Building Close Relationships with Our Customers"

"Building Close Relationships with Our Customers"

-

"Transforming the Construction Sector with DX"

"Transforming the Construction Sector with DX"

-

"Bringing Ever-More Joy to Travel in Japan"

"Bringing Ever-More Joy to Travel in Japan"

-

"Regeneration" Arises from New Construction

"Regeneration" Arises from New Construction

-

"An Enduring Spirit of Hospitality"

"An Enduring Spirit of Hospitality"

-

"Collaborating with 16 creators invited from around the world"

"Collaborating with 16 creators invited from around the world"

-

"Passing Down Hometown to Future Generations with Renewable Energy"

"Passing Down Hometown to Future Generations with Renewable Energy"

-

"The twenty-first century will be wind, solar, and hydro"

"The twenty-first century will be wind, solar, and hydro"

-

"Be a Pioneer in the Design Revolution"

"Be a Pioneer in the Design Revolution"

-

"Building better places to live through partnership between the public and private sectors"

"Building better places to live through partnership between the public and private sectors"

-

"Supporting the foundations of the nation"

"Supporting the foundations of the nation"

-

"Continuing to work the rest of life"

"Continuing to work the rest of life"

-

"Doing our best to support post-disaster reconstruction"

"Doing our best to support post-disaster reconstruction"

-

"Defying common wisdom in housing construction"

"Defying common wisdom in housing construction"

-

"Develop the American market!"

"Develop the American market!"

-

"Exporting Japanese industrial parks"

"Exporting Japanese industrial parks"

-

"Industrializing agriculture"

"Industrializing agriculture"