"Industrializing

"Industrializing

agriculture"

Daiwa House Industry, whose business operations center on construction,

has developed a vegetable-grower unit aimed at helping "industrialize" agriculture.

This work was undertaken by our research staff, who boldly tackled a large number of difficult issues.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

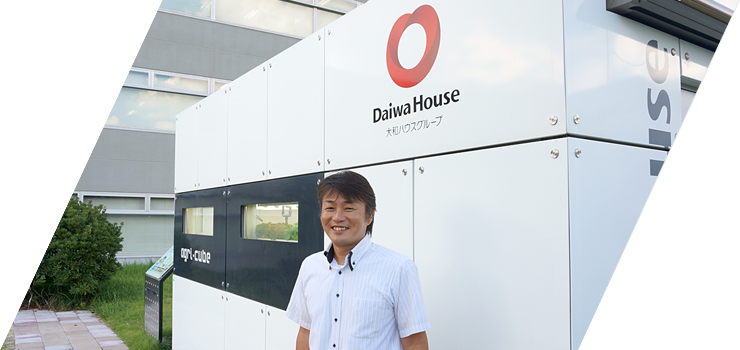

Construction company builds vegetable-growing factories

You don't need a field to grow vegetables – just an area the size of one parking space. We're not talking about greenhouses here. Our "agri-cube" product is a scientifically designed vegetable-grower unit fitted with all the equipment needed for efficient hydroponic cultivation, including special lighting. Shigeto Inoue of our Central Research Laboratory, who has played a leading role in the development of the "agri-cube," has succeeded in producing a commercially viable vegetable-growing factory, a feat that had previously eluded the staff not only of Daiwa House Industry but also of Group-member Daiwa Lease, whose staff have cooperated in this project.

At the press release for the "agri-cube," faced with a number of journalists who were wondering why on earth a construction company like Daiwa House would develop a vegetable-growing factory, Mr. Inoue declared that the development of the "agri-cube" had opened up completely new prospects in the agricultural industry.

"The industrialization of agriculture"

Press conference to announce the "agri-cube"

Two-and-a-half years ago, Mr. Inoue had been charged by Daiwa House Chairman and CEO Takeo Higuchi with the mission of finding a way of industrializing agriculture. At first, he didn't know what to do or where to start.

But then he began to realize that, against the background of serious social problems – Japan's declining food self-sufficiency, growing concern over food safety, and the aging of the country's work force in the farming sector – here was a chance for the Daiwa House Group to offer a solution to these issues via its business operations.

Mr. Inoue worked closely with the staff of the Management Planning Department – which is responsible for developing new business operations – to research ways of industrializing agriculture. After six months of such efforts, they had accumulated a vast amount of data, but no concrete achievements. The business strategies that the staff of the Management Planning Department took for granted – even the technical jargon they used – were completely foreign to Mr. Inoue, and he took to reading books in search of the path to a breakthrough. In fact, he read more books during this period than he had ever done before. It was while reading a book one day that he came across words that shone a light on the path that lay before him.

When you are unsure, go back to the basics

Those words were: "When you are unsure, go back to the basics." He thought: "Yes, of course! When all your experiments keep failing, to start again from the beginning may seem like a long way round, but it's actually the best shortcut." Suddenly, the fog lifted, and he could see the way forward.

Just around that time, Mr. Inoue had recently been to a trade show where he had seen a vegetable-growing factory, and his reaction was simultaneously to see future potential and also to harbor doubts. "Why haven't these things become popular and widespread before now?" Thinking about it, a simple answer presented itself. The problem lay in the cost of the necessary initial investment in the equipment, as well as a building to house the equipment, plus the running costs.

This was where Daiwa House's expertise came in, he thought. The concept of the "industrialization of construction" lay at the core of the very foundation of Daiwa House. By "pre-manufacturing" most of the materials for a house in a factory, ready for simple assembly on site, the Company had been able to realize high-quality homes faster and at lower cost than with the previous methods. Mr. Inoue saw that the concept could equally be applied to the production of food. Instead of producing food in fields (the meaning of "agriculture") the answer was to develop an original form of pre-manufactured factory for growing vegetables.

A tasting of the vegetables grown in the unit with a group of chefs from major hotels

In April 2009 they commenced a process of trial and error with the goal of creating a commercially viable product. Working together with Daiwa Lease, they came up with one idea after another and put them into trial production. Just at that time, they came across a temporary unit created by Daiwa Lease. As soon as he saw it, Mr. Inoue exclaimed: "That's it!" and decided to use it in a space they had reserved at a trade fair showcasing greening and technologies. They manufactured the unit at a factory and transported it to the trade fair location, without need for assembly at site. In this way, they recreated Daiwa House's first major success, with a product that was high-quality, quickly manufactured, and inexpensive.

They paid particular attention to the size of the unit. It was necessary to create a unit that could be transported in a four-ton truck but would still contain all the required vegetable-growing shelves and air-conditioning equipment. To reduce manufacturing costs, existing components and materials used in housing and other construction products were employed. For the entrance/exit to the growing room, they used a bathroom door from an existing Daiwa House housing product.

When the project was just about completed, they encountered frustrating design problems, and eventually came up with a futuristic design whose exterior could be customized. They arranged a tasting of the vegetables grown in the unit with a group of chefs from major hotels, and constant readjustment of the formula for the nutrient solution used in cultivating the vegetables was conducted right up to the final stage.

In April 2012, two-and-a-half years after the Company's management made the decision to embark on the industrialization of agriculture, the "agri-cube" was born.

Discovering new possibilities within oneself

What kept Mr. Inoue going during the long and exhausting process of developing the "agri-cube" was the cooperation provided by the researchers at Daiwa House and the production staff at Daiwa Lease.

Yoshitomo Ono, one of those researchers, was initially rather undecided about the merits of this unusual project. "At first, it seemed that the idea of a vegetable-growing factory had nothing in common with construction – the Company's main business line – but then I realized that precisely because it was completely new departure, we had an opportunity to exercise our imagination and creativity in a completely unfettered way. At any rate, I determined to find a concrete solution to the problems faced by society. At Daiwa House, we were determined to find a concrete solution to the problems faced by society. The Company has grown to its present scale by repeatedly solving new problems in this way, and this is why I intend to always ask myself what the next new thing is."

Young researcher Shinya Okamura studied vegetable cultivation techniques at college. "I conducted research at college into the metabolic rhythms of plants. I continued these studies after joining Daiwa House, and I have been lucky enough to succeed in cultivating completely new products."

Test model of the "agri-cube"

Hirotoshi Morita, who was working in the Product Development Section of Daiwa Lease during the development of the "agri-cube," put considerable effort into designing a system of mass-production. "When I receive a difficult request it makes me want to overcome the problems involved. The challenges were to cram as many features and as much function as possible into a small unit, and to find the best exterior design. There was plenty here to stretch my capabilities to the utmost."

Yoshinobu Kumagaya of Daiwa Lease, who had taken part in the project right from the planning stage, has made good use of his agricultural studies, and is now thinking carefully about the next step to take. "I believe that it might be possible to reactivate regional communities through a new approach to agriculture. As long as we are alert to the whole spectrum of social changes on a day-to-day basis, and put our efforts into studying their implications, we should be able to respond immediately when a new theme makes its appearance."

These five men formed a single team. They worked all through the night to be able to present a model vegetable growing factory at one of our commercial facilities. They talked and exchanged information and insights that crossed the boundaries between their personal job categories. Together, they watched the sun come up, and through their development of the "agri-cube," each one of them discovered new possibilities within himself.

Creating new value

In developing the "agri-cube," we envisaged the potential customers for this product as being companies in the foodstuffs industry whose managements had been looking into the possibilities of vegetable-growing factories, as well as restaurants. After announcing the product's development, however, we found it was also drawing attention from unexpected directions.

Charitable foundations and organizations involved in providing care for persons with disabilities were looking to use such factories as places that could offer a new form of employment for disabled people. Also, institutions of further education as well as research institutions saw the advantages of the "agri-cube" for use in their research facilities, as the unit is compact and does not require connection with outside equipment. Because Japanese technology in the sphere of vegetable-growing factories enjoys a high reputation overseas, we also received inquiries from Southeast Asia and the Middle East.

Clearly, many people in Japan and other countries were quick to realize the potential of the "agri-cube."

Going forward, Mr. Inoue hopes to conduct research in the fields of foodstuffs, water resources, and renewable energy. For instance, he believes that the production technologies and environmental control technologies used in vegetable growing factories could make possible the efficient cultivation of non-edible crops on unused farming land, and that these crops could be employed as biomass material for the generation of energy. He also harbors a numbers of other startlingly ambitious dreams, such as applying the concept of industrialization to the fisheries industry.

Shigeto Inoue sees no essential difference between agriculture, fisheries, or the energy sector. He wants to create new value in every field – value that does not yet exist anywhere in the world – because this sort of undertaking is the most important mission for any researcher at Daiwa House Industry.

The "agri-cube" vegetable-grower unit

* Information on the "Spirit of Hearts" is at the time of the coverage.

-

"A Free Hand to Design a New World of Luxury Houses"

"A Free Hand to Design a New World of Luxury Houses"

-

"The next mission in construction business"

"The next mission in construction business"

-

"An Athlete’s Flying Start to His Second Life"

"An Athlete’s Flying Start to His Second Life"

-

"Tackling the Challenges of Carbon Neutrality"

"Tackling the Challenges of Carbon Neutrality"

-

"Building Close Relationships with Our Customers"

"Building Close Relationships with Our Customers"

-

"Transforming the Construction Sector with DX"

"Transforming the Construction Sector with DX"

-

"Bringing Ever-More Joy to Travel in Japan"

"Bringing Ever-More Joy to Travel in Japan"

-

"Regeneration" Arises from New Construction

"Regeneration" Arises from New Construction

-

"An Enduring Spirit of Hospitality"

"An Enduring Spirit of Hospitality"

-

"Collaborating with 16 creators invited from around the world"

"Collaborating with 16 creators invited from around the world"

-

"Passing Down Hometown to Future Generations with Renewable Energy"

"Passing Down Hometown to Future Generations with Renewable Energy"

-

"The twenty-first century will be wind, solar, and hydro"

"The twenty-first century will be wind, solar, and hydro"

-

"Be a Pioneer in the Design Revolution"

"Be a Pioneer in the Design Revolution"

-

"Building better places to live through partnership between the public and private sectors"

"Building better places to live through partnership between the public and private sectors"

-

"Supporting the foundations of the nation"

"Supporting the foundations of the nation"

-

"Continuing to work the rest of life"

"Continuing to work the rest of life"

-

"Doing our best to support post-disaster reconstruction"

"Doing our best to support post-disaster reconstruction"

-

"Defying common wisdom in housing construction"

"Defying common wisdom in housing construction"

-

"Develop the American market!"

"Develop the American market!"

-

"Exporting Japanese industrial parks"

"Exporting Japanese industrial parks"

-

"Industrializing agriculture"

"Industrializing agriculture"