Daiwa House Group TechnologyThe first product from Daiwa House Industry The Pipe House- Helping support Japan's high economic growth –

Daiwa House Group TechnologyThe first product from Daiwa House Industry The Pipe House- Helping support Japan's high economic growth –

After World WarⅡ, Japan was hit by a super typhoon that damaged or destroyed many thousands of homes. Nobuo Ishibashi, the founder of Daiwa House Industry, noticed that rice plants and bamboo bent but did not break in the face of strong winds, because of their cylindrical structure. This gave him the idea of developing the Pipe House, a standard-type temporary structure that employed a steel-pipe framework. The component parts of frames and walls were produced at the Company's factory, and then assembled on site using special metal fittings. The Pipe House, which embodied the concept of the "industrialization of construction," was used for warehouses and offices, mainly operated by the government, and it supported Japan's development from post-war reconstruction to the period of high economic growth.

When the Pipe House was developed, Japan's post-war reconstruction was in full swing, but in 1950 a serious natural disaster made clear the challenges faced by the country's construction industry. Typhoon Jane, with a maximum instantaneous wind speed of 59.1m/s, damaged 120,000 houses in the Kansai region, of which 20,000 were completely destroyed. More than 870,000 people were affected.

Nobuo Ishibashi, the founder of Daiwa House Industry, noticed that rice plant stems and bamboo remained unbroken despite the strength of the winds, which had been fierce enough to cause the tragic collapse of wooden houses all around. Ishibashi realized that what these plants had in common was that they were cylindrical and hollow, and that, in the same way, he could design a sturdy building using steel pipes. In April 1955, five years after initial conception, Daiwa House Industry launched the Pipe House simultaneously with the Company's founding.

In the background to this product's development was the building materials situation that Japan faced at that time. Indiscriminate deforestation during the war had devastated forests, and in January 1955, the government decided on a policy of rationalizing the use of timber resources to prevent their depletion and promoting the use of alternative resources. Construction using steel pipes also met the needs of the times.

Features of the Pipe House

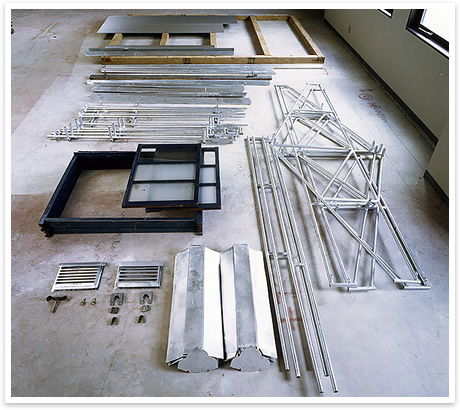

- Use of components for frames, roofs, walls, floors, fittings, etc. that can be assembled on site

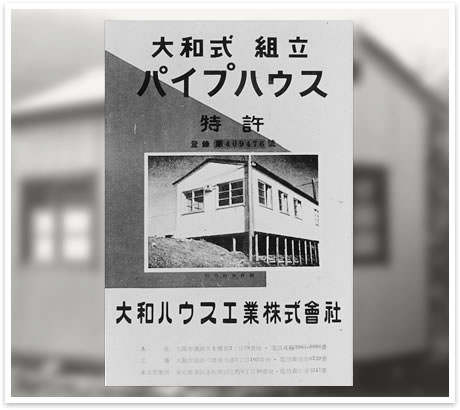

- A patented construction method in which pillars and trusses consisting of steel pipes with thin walls (22.7 mm to 27.3 mm in diameter) are assembled on site using special metal fittings.

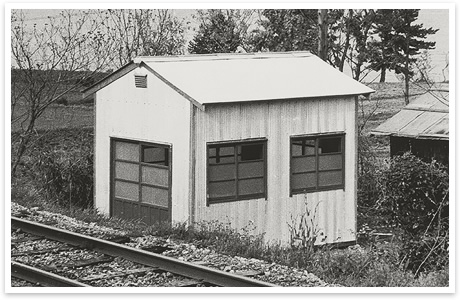

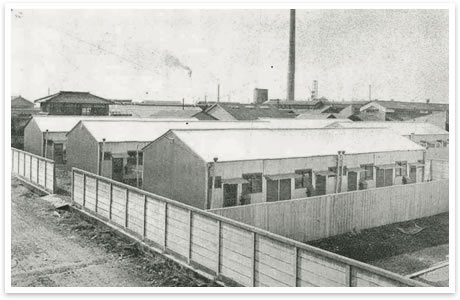

Products in our Pipe House series — which could be built quickly, cheaply, and easily with the same specifications and to a guaranteed uniform quality, thanks to the industrialization of construction — were adopted by a variety of public- and private-sector companies that were expanding their operations nationwide during Japan's high economic growth period. In particular, the Japanese National Railways (currently JR) was under pressure to build simple warehouses and garages at stations and along the company's railway network covering the entire country. When customers placed an order for a Pipe House, they needed only assemble the standardized parts. Construction was thus incomparably faster than with conventional methods, and this met JNR's needs.

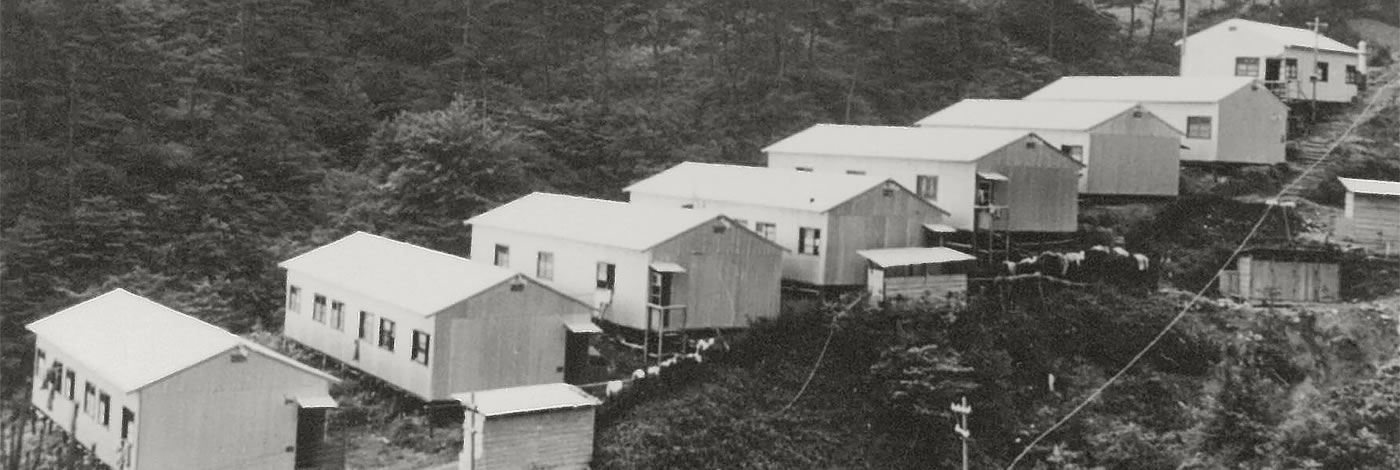

The Pipe House was also used as temporary housing, with wooden window frames attached and hardboard interiors. In 1956, the year after its launching, the product was selected for use as worker housing at the construction site of the Kurobe River No. 4 Power Plant (commonly known as the Kuroyon Dam), which Kansai Electric Power Co. planned to build in Tateyama Town, Toyama Prefecture. Because the valley where the dam was to be built is hemmed in by steep hillsides, the Pipe House was suitable, as it could be constructed quickly with few materials and was strongly wind-resistant. In this way, Daiwa House continued to protect people who risked their lives working in harsh conditions.

The use of the steel pipe construction technology developed by Daiwa House in its Pipe House has evolved from small-scale temporary structures like the Pipe House to its use in full-scale general construction, employing large-diameter pipes. In 1957, we received an order from a sake brewery in Nishinomiya City, Hyogo Prefecture for construction of a large-scale building with an area of approximately 724 square meters. In the background to this was the establishment in the previous year (1956), of the JIS (Japanese Industrial Standards) for structural carbon steel pipes, which made it possible for the first time to use steel pipes as building materials. Thanks to this, our technology was approved by the recently established Japan Light Steel Frame Building Association, and we were able to erect Japan's first steel pipe structure building.

The foundation work commenced on April 28, 1957 and the building was completed on June 15 of the same year. Thirty-eight years later, on January 17, 1995 the magnitude 7.3 Great Hanshin-Awaji Earthquake occurred, but Japan's first steel-pipe structure building remained undamaged.

Following a large-scale natural disaster in 1959, the Pipe House came into its own as a form of emergency temporary housing. The Isewan Typhoon, an exceptionally intense tropical cyclone, hit Japan's Chubu and Kinki regions, causing about 5,000 deaths and leaving roughly 150,000 houses destroyed or severely damaged. Following this, the Company received a large number of orders for Pipe Houses, which can be built cheaply and in a short time, and are thus suitable as emergency temporary housing. When a disaster strikes, speed is of the essence. Daiwa House Industry stopped normal operations and put its full efforts into building Pipe Houses as quickly as possible.

Through this experience, Daiwa House Industry acquired know-how in disaster relief. At the same time, I became strongly aware that it was our mission to provide emergency temporary housing in the event of a disaster, and thereby protect the livelihoods of people affected by the disaster.

In 2011, the Pipe House and the Midget House were registered as important science and technology historical materials (registration number: No. 00081) by the National Museum of Nature and Science, and were given the nickname Technology Legacy to Future Generations. They were recognized as important signposts in the development of science and technology in Japan during the early days of the country's prefabricated housing industry.

The Pipe House was the first product created following the founding of Daiwa House Industry, and it played a major role in advancing the "industrialization of construction." Beginning with warehouses and temporary housing, it later became the cornerstone of steel pipe structures as a whole. And it remains the ancestral model for current construction business formats such as logistics facilities, factories, and offices.

Reasons for registration as important science and technology historical materials

Among the prefabricated building developments carried out by the public and private sectors, the Pipe House was the first building originating from the private sector that achieved business success. It was assembled from steel pipe columns and trusses with wall diameters of 22 to 27 mm. The Pipe House started as a warehouse, then came to be used as temporary housing, and later became the cornerstone of steel pipe structural architecture. It is a valuable and pioneering entry in the history of the prefabricated construction technology that has blossomed in Japan.

Examples of the Pipe House and Midget House are on display at the Daiwa House Industry Central Research Laboratory in Nara City.

The Group's facility construction solutions business began with the Pipe House. We offer a total design, construction and maintenance service for a wide variety of facilities, tailored to individual business needs.