Daiwa House Group TechnologyThe Origin of Japan's Prefabricated House Industry The Midget House- Children's Study Room that could be erected in three hours for only 110,000 yen -

Daiwa House Group TechnologyThe Origin of Japan's Prefabricated House Industry The Midget House- Children's Study Room that could be erected in three hours for only 110,000 yen -

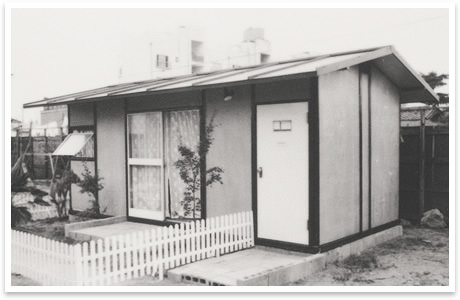

The Midget House is a product that was created to solve a housing problem. The average home had become cramped due to the rapid increase in the number of children per family due to the postwar baby boom. The product was launched in 1959 as a detached children's study room, and became a major market success. This was because it could be erected in only three hours – which was revolutionary for the construction industry at the time – and was priced at a mere 110,000 yen or so. The Midget House was the starting point and cornerstone of today's prefabricated homes.

When the Midget House was developed in 1959, Japan was suffering from a lack of school classrooms, due to the baby boom that had begun in 1947. Upon being consulted on this issue by a board of education, Daiwa House Industry founder Nobuo Ishibashi proposed the concept of a “Movable classroom.”

The idea of relocating classrooms when the number of students in a particular grade increases as the pupils from elementary school go on to junior high school became reality with the use of the prefabricated construction technology that the Company had developed in its Pipe House project. However, Ishibashi was still concerned about the environment of children belonging to the baby boom generation, and he saw this as a social issue that needed to be resolved.

One day in early summer, Ishibashi, who was fishing for ayu, saw many children playing by the river instead of fishing. When he asked some of them why they were here, they told him that they were playing outside because their house was cramped and they didn't have a space of their own. Saying to himself “Aha!”, Ishibashi saw the core of the problem.

Problems that occur at school also occur at home. The fact that children don't have a space of their own at home means that their parents are also unable to relax and put their feet up. Although the economy was picking up at that time, few families had the financial leeway to move to a house large enough for everyone. Musing on this situation, Ishibashi hit on the idea of marketing a study room that could be assembled as an annex to a house.

Nobuo Ishibashi gave two preconditions to the staff member in charge of development. The product had to be capable of assembly in three hours, and the unit price had to be under 40,000 yen.

At that time, it was common for both new houses and extensions to be built under contract, and to be made out of wood, and it went beyond the bounds of conventional wisdom to try to create a "product" using a steel-frame prefabricated construction method. Because of this, apart from the short construction period, it was a tough hurdle to achieve a steel-frame structure with a price per square meter in the same range as a medium-price wooden house.

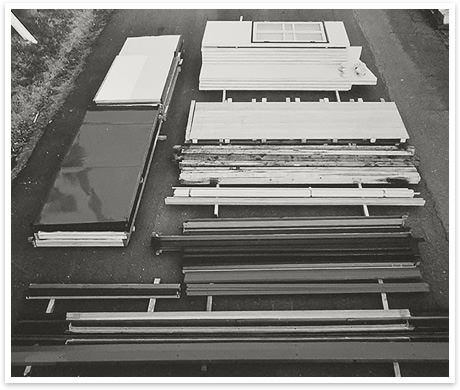

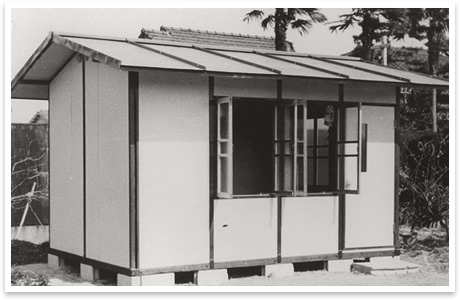

After repeated trial and error, the Midget House finally came into being. We were able to meet the two preconditions by adopting a panel construction method that used lightweight shaped steel – which was beginning to come on the market at that time as a building material – and hardboard that had been oil-tempered (heat-treated by soaking in oil).

At the same time, it was also necessary that this product could be supplied in large quantities. Therefore, by keeping the size to about ten square meters or less, we eliminated the need for official "building confirmation" by the authorities. We also designed the Midget House so that it could be loaded on a truck and delivered straight to the construction site as soon as it had been made at the factory.

The price was 108,000 yen for the 4.5 tatami mat (7.4 sq.m.) type and 118,000 yen for the 6 tatami mat (9.9 sq.m.) type. To put these figures in perspective, the starting monthly salary for university-graduate national government employees in those days was 10,200 yen.

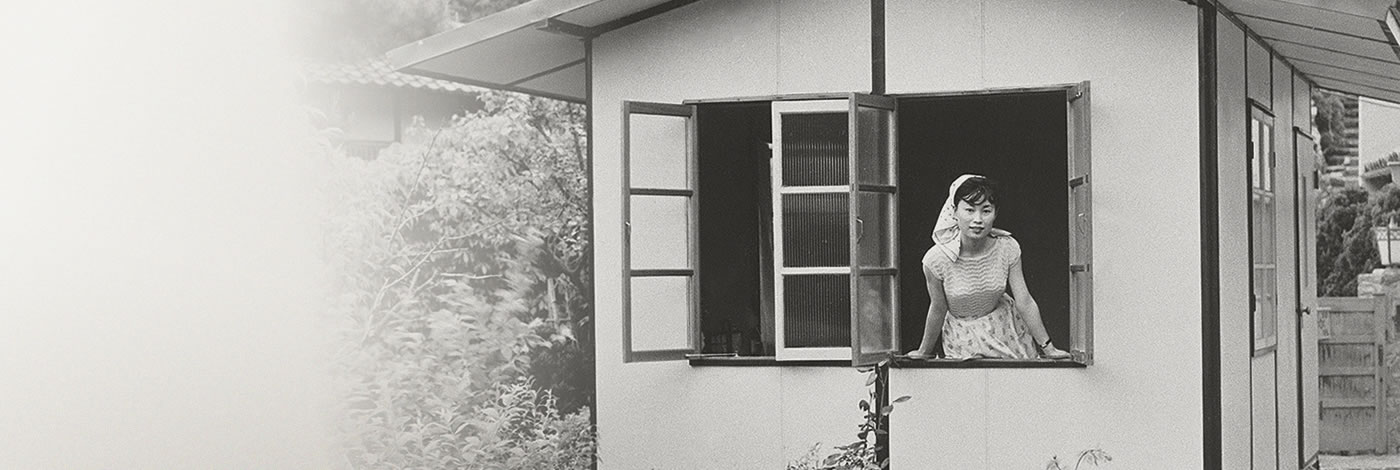

In addition, since this product is a "children's house," the dimensions were small. The roof slope and eaves were designed to match the exterior design. At the time, the double windows gave the "feel" of the Western way of life that people yearned for at the time.

| Types | 4.5-tatami type | 6-tatami type |

|---|---|---|

| Price (when first launched) | ¥108,000 2.72m×2.72m |

¥118,000 2.73m×3.63m |

| Foundations | Concrete | |

| Flooring | Base: cypress, Floor support beams: cedar | |

| Walls | Pillars, wall panels | |

| Roofs | Roof panels, ridge flashing | |

| Fittings | Windows, entrance/exit | |

| Painting | Steel components: OP finish, wooden parts: varnished | |

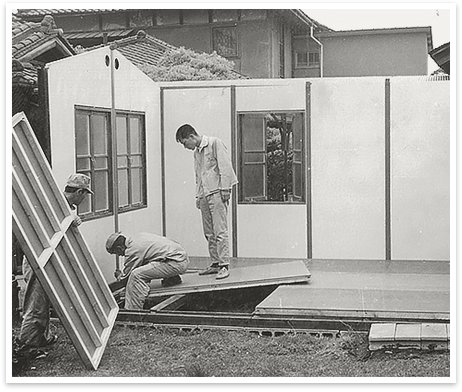

Method used to assemble Midget House in three hours

- 1. At the factory, produce panels, each of which incorporates outer and inner walls

- 2. Transport components to site, using small truck that can pass through narrow streets

- 3. Lay about 40 concrete blocks as foundation

- 4. Set lightweight steel pillars resistant to swaying in strong winds, and install wall panels between pillars

- 5. Put roof on, and finish ceiling and floor by installing panels

- 6. Install window frames and doors (entrance/back door)

- 7. Lay floor

- 8. Completion

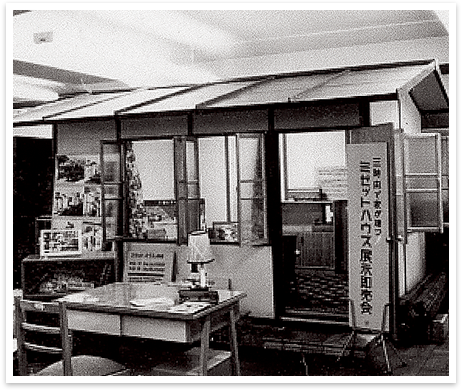

The Midget House, which became a completed product thanks to Nobuo Ishibashi's insight and the creative ingenuity of the development staff, went on sale at twenty-seven department stores nationwide in October 1959. It immediately attracted a great deal of attention, and became a talking point in the media, which highlighted its originality. On the other hand, the majority opinion among observers in the construction industry was that this product would not sell, as it was difficult to accept it as a house according to the conventional wisdom at the time. In fact, however, the Midget House was bought by many families, and it became a runaway success exceeding even Ishibashi's own expectations.

The Midget House was not just a children's room that helped solve the problem of a lack of space in the home. In response to customer requests for the fitting of a toilet and/or a kitchen, Daiwa House developed the Super Midget House for newlyweds, and then later further developed the product into a full-fledged prefabricated house.

This success proved that the method of constructing homes as a "product" – as opposed to the conventional system in which individual houses are ordered and constructed under contract – was well-received by consumers. After hearing about this, a series of companies from various industries entered the prefabricated construction business. In addition, manufacturers that provide building materials for prefabricated buildings, such as those used in dry construction methods, were established one after another, thus creating today's prefabricated housing industry.

In September 2011, the Midget House and the Pipe House were registered by the National Museum of Nature and Science, an independent administrative agency, under the category of "early prefabricated houses" as important science and technology historical materials (nicknamed Technology Legacy to Future Generations; registration number 00081). The museum selects valuable materials that demonstrate the development of Japanese science and technology. For example, the world's first wireless telephone and Japan's first domestically produced large-scale rocket were selected as cultural assets that have had a great impact on society. It is a matter of great pride to us that the Midget House has taken its place among this list of achievements.

We further developed the Midget House – which had been the starting point for prefabricated housing in Japan – into a variety of products, including single-family houses, temporary housing, and retail outlets. The Midget House, which was inspired by our founder Nobuo Ishibashi's desire to solve social issues, accelerated the "industrialization of housing" and made possible great progress in Japanese housing. This was an innovation that could be called a “housing revolution.”

Reasons for registration as important science and technology historical materials

Among the prefabricated building developments conducted by the public and private sectors, this was the first building originating from the private sector that was commercially successful. The Midget House uses C-shaped steel pillars between which wooden cross panels are fitted, forming the walls. It was sold for use as a detached room, such as a study room. The product was a runaway success, thanks to the fact that it cost only 118,000 yen and took only three hours to erect. It is a valuable and pioneering entry in the history of the prefabricated construction technology that has blossomed in Japan.

Examples of the Pipe House and Midget House are on display at the Daiwa House Industry Central Research Laboratory in Nara City.

Daiwa House Industry's homes, which started with the Midget House. Comfortable homes with spacious interiors.