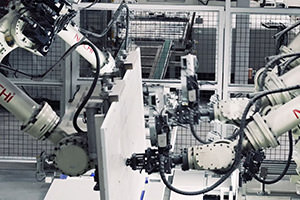

Daiwa House Industry manufactures every house individually in highly systematized factories. Work is done inside and out of the elements for stable quality. Industrial robots and seasoned crafters work side-by-side to precision-fabricate building materials. And dedicated experts carefully inspect output at every process to ensure that only top-quality materials make it to building sites.

Daiwa House’s xevoΣ line maintains new-build seismic resistance even after consecutive intensity-7 jolts.(※1)

Electrodeposition is used to paint principal structural parts to ensure 75 years of service life(※2)

(※1) For details on "tremors equivalent to a seismic intensity of 7,"click here.

(※2)In the Japan Housing Performance Indication Standards, if measures are taken to ensure that the structural frame will last for three generations (75 to 90 years), the highest grade (grade 3) will be rated.

Robots enhance precision of welds and machined surfaces down to the millimeter

Electrodeposition gives materials the industry’s highest-grade protection against corrosion

The Daiwa House Group is implementing a carbon neutrality strategy to guide it to net-zero greenhouse gas emissions. To achieve carbon neutrality at plants, the Group pursues energy-conserving programs deploying D’s FEMS*. We are switching from fossil fuel-burning to electricity-powered equipment, and renewable energy systems are installed when plant buildings are renovated or rebuilt.

* Daiwa House’s unique energy management system

Daiwa House is replacing older plants with environmentally friendly D’s SMART FACTORY.

Daiwa House was recognized with the 2013 Minister of Economy, Trade and Industry Award, the highest among the Energy Conservation Awards

Daiwa House Group plants nationwide achieve RE100 targets (100% renewable energy usage)(※3)

(※3)An international initiative that aims to procure 100% of the energy consumed in business activities from renewable energy.

We’re decarbonizing by generating power with our buildings and using it efficiently on our production lines

Adopting roof and wall greening too, we are working to build environmentally friendly factories

Our factories also produce building components for logistics, business and corporate facilities. Fabrication of components for general purpose buildings like warehouses and offices is performed by robots and people working together. Standardized components for modular buildings used as roadside shopping facilities are factory-manufactured to ensure quality and shorten construction turnaround. The experience and expertise gained from large-scale construction projects deploying these advanced technologies also get put to work in creating safe, comfortable living spaces for homeowners.

Our factories produce large components requiring precision machining and welding expertise, too

Robots’ welding large columns enhances process and energy efficiency

MLIT grade certification is a program to assure the quality of steel structural members fabricated at certified steel-frame manufacturing facilities. There are five categories, each with a specific scope depending on building size, plate thickness, and steel type. Daiwa House Industry’s Ibaraki Ninomiya Plant acquired S-grade certification, the highest, in 2019.

The five grades:

Daiwa House Industry’s plants acquired ISO9001 certification plants in 2002. It had previously been certified under ISO9002, a set of international quality assurance standards, in 1996 at its Production and Procurement Department and all its domestic plants in recognition of its integrated production of high-quality products.

Daiwa House Industry’s Production and Procurement Department and all its plants were certified in 2001 for ISO14001, a set of environmental management systems standards.

Housing technologies

Construction technology

Urban planning, multi-purpose development projects, and regional revitalization